One of the most important values for us at Greenchemicals is training.

This can be done in many different ways, from in-depth courses at the Academy to courses for the company team. Or, even more simply, by answering some of the questions we are asked at trade fairs, by email, or in person.

For example, to understand the differences between certain types of plastic additives, such as antistatic and flame-retardant additives, and to comprehend their main characteristics.

Antistatic additives

Let’s start with a basic assumption: plastic is an electrical insulator and, as it does not conduct electricity, it tends to have problems with static electricity build-up.

For this reason, antistatic additives are often added to polymers to reduce accumulated static electricity and increase surface conductivity.

This reduces all the risks associated with static electricity: contamination with dust and deterioration of the product’s appearance, difficulties during processing, damage to electronic components, and fire risk.

There are two main categories of antistatic additives:

- internal: these are added to the polymer matrix during compounding or processing, and slowly migrate to the surface of the polymer, forming a thin conductive layer that prevents the accumulation of electrical charge

- external: these are applied to the surface of the finished product (usually as a spray or coating) and quickly form a temporary antistatic coating.

At Greenchemicals, we offer various types of internal antistatic additives: write to us now at salesteam@greenchemicals.green

Flame retardants

Flame retardants, on the other hand, reduce the spread of flame in plastics through various mechanisms. These are prevention and safety additives, as their effect is only visible when the plastic burns (and if it contains them, it burns more slowly). Being a petroleum derivative, plastic needs flame retardants to overcome this critical issue.

Flame retardant mechanisms and results

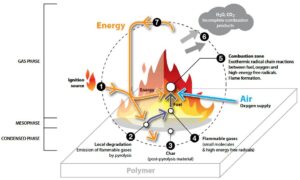

Three elements are required for a fire to occur: an ignition source (fire, spark, something that provides heat), an oxidizing agent (oxygen, which acts as a combustion agent), and a fuel (a substance capable of igniting, such as plastic).

Flame retardants work in different ways, depending on their type, composition, and application.

We will leave a detailed explanation of these mechanisms to other posts. For now, let’s focus on the results obtained with flame retardants:

- they make it more difficult for combustion to start

- they slow down the spread of flames to other materials

- they produce less smoke and, in the case of non-halogenated flame retardants, they reduce the risks associated with smoke inhalation

Although antistatic agents prevent the risk of fire, they do so only because they act on static electricity, which can cause sparks. Flame retardants, on the other hand, act precisely as safety and fire prevention additives.

At Greenchemicals, we produce traditional and halogen-free flame retardants. Discover our range by clicking below!

For more information, contact us now at salesteam@greenchemicals.green