For those working in the plastics industry, ensuring product heat stability is essential.

The aim is to prevent excessive stress in the material being processed and ensure it maintains stable mechanical and chemical properties.

This is particularly critical in applications such as automotive under-bonnet components, electronic and electrical devices, pipes and fittings for hot fluids, sterilisable packaging, and building materials exposed to high temperatures. In all these cases, the polymer must maintain its performance even under demanding thermal conditions.

There are several ways to make polymers more resistant to thermal stress, depending on the specific requirements. One of the most effective methods is to add targeted additives.

What happens if the polymer degrades?

Degradation is a process that causes a change in the polymeric material, even if limited, which has a significant effect on its properties.

The polymer may therefore exhibit alterations to its mechanical, physical, and optical characteristics.

Such degradation is generally caused by thermal or mechanical stress, exposure to UV rays, oxidation, or interaction with a chemical substance.

This is where antioxidants come into play.

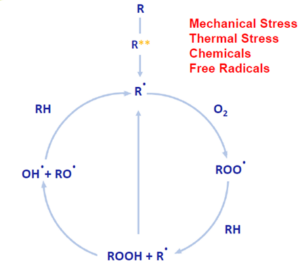

Antioxidants and radical processes

Antioxidant additives can be used to prevent or slow down the thermo-oxidative degradation of polymers. They can be used during production and transformation phases.

There are two types of antioxidants.

Primary antioxidants act as hydrogen donors, neutralising the free radicals that initiate and propagate oxidative degradation. Secondary antioxidants work synergistically with primary antioxidants to decompose hydroperoxides before they can generate new radicals.

Together, they increase the material’s intrinsic antioxidant properties, achieving the stability and protective effect required by many industrial applications.

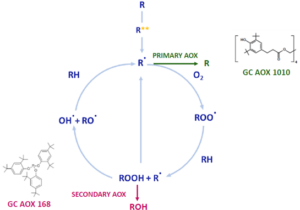

Below is an example of Greenchemicals’ antioxidants in action:

In this diagram, we see GC AOX 1010, which prevents the radical from reacting with oxygen (a primary antioxidant). If a percentage of peroxide is formed, the secondary antioxidant GC AOX 168 intervenes by forming an alcohol (ROH), i.e. an inert molecule for this process.

These two products therefore maintain the polymer’s stability, enabling it to be processed without degradation.

Discover our range of antioxidants!

Other stabilisation options

The thermal resistance of polymers can be achieved in two other ways.

One option is to use mineral fillers, such as inorganic powders like talc, wollastonite, magnesium hydroxide and calcium carbonate. Glass fibre is a particularly effective filler as it can increase tensile strength, rigidity and thermal stability.

Another strategy is to add small amounts of high-heat-resistant polymers to the main compound to ensure compatibility between the materials.

We can support you in choosing the best antioxidant additive for your needs to improve the longevity of polymers. How?

We take into account the best synergies between primary and secondary antioxidants for the specific polymer to ensure stability during manufacturing processes (e.g. extrusion and moulding) and quality in the final product.

Contact us for more information at info@greenchemicals.green